Dry electrodes and wet electrodes have their own advantages and disadvantages. The dry electrode process requires fewer steps and eliminates the need for NMP solvent, resulting in a simplified process and avoiding electrode drying and solvent recovery. Dry cathode and anode materials have higher energy density and superior electrochemical performance. Under laboratory conditions, dry electrodes demonstrate better cycling performance, durability, and impedance.

Dry Electrode Process: Efficiency vs. Complexity

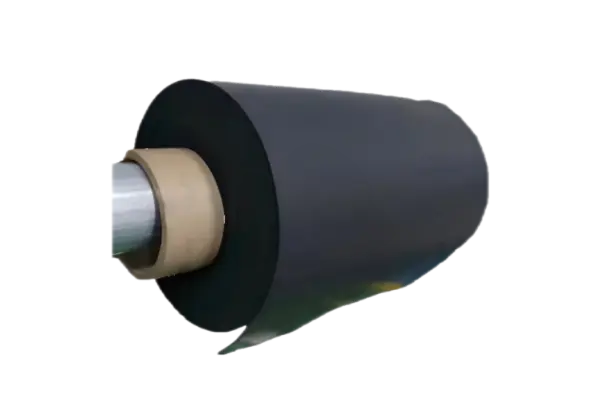

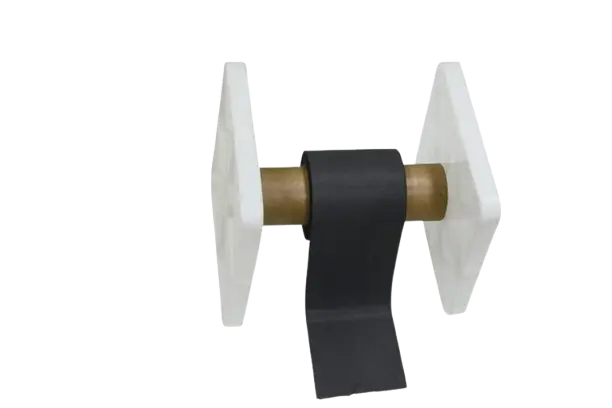

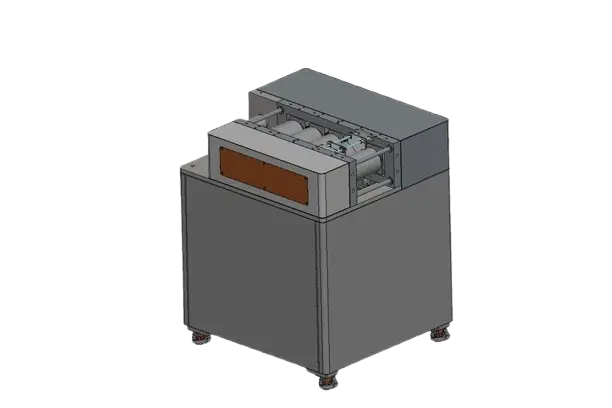

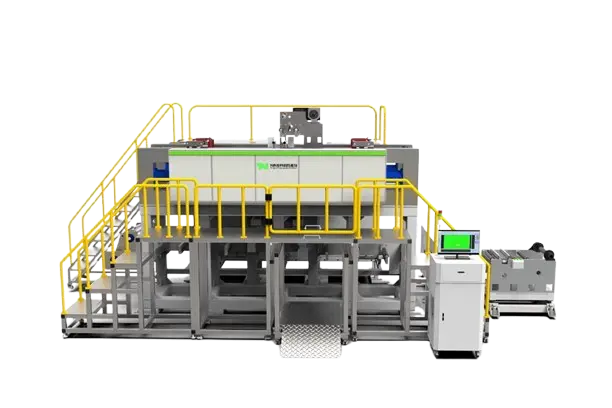

The dry electrode process significantly enhances production efficiency by removing solvent dependency. Without the need for NMP or similar chemicals, manufacturers can eliminate drying chambers and solvent recovery systems, streamlining the process into three key steps: dry mixing, coating, and roll pressing. In contrast, wet electrode production relies on solvent-based slurries, demanding additional time and energy for drying, as well as complex solvent recycling processes to mitigate environmental impact. The result is a more resource-intensive, costly, and less sustainable method compared to the streamlined dry approach.

Performance Benefits of Dry Electrodes

Dry electrodes outperform wet electrodes in multiple critical areas. Their dense structure enhances energy density by preventing binder redistribution—a common issue in wet processing that can weaken electrode integrity. Lab tests confirm that dry electrodes exhibit superior cycling stability, reduced degradation, and lower impedance, leading to longer-lasting and more efficient energy storage solutions. Additionally, the absence of residual solvents improves ion transport, reducing internal resistance and boosting charge/discharge efficiency. From a production standpoint, DBE battery electrode processing increases throughput by skipping the time-consuming drying phase required in wet electrode manufacturing. Since no solvents are used, hazardous emissions are eliminated, making dry electrode production cleaner and more energy-efficient.

Dry Electrodes Applications in Advanced Energy Storage

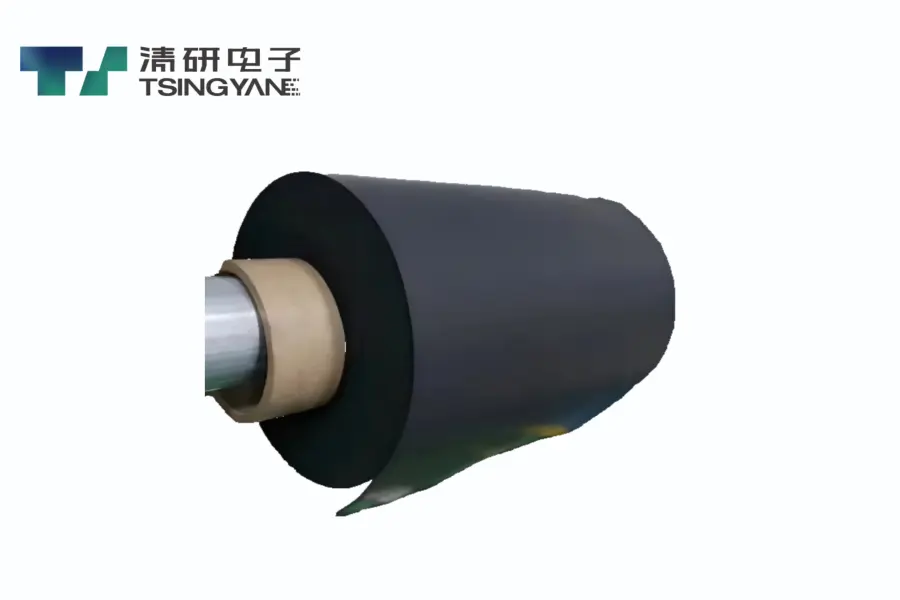

The high conductivity and extended cycle life of dry electrodes make them ideal for high-performance supercapacitors. In battery applications, including lithium-ion and solid-state batteries, dry battery electrode technology enables higher energy density while reducing production time and costs. Innovations like Tsingyan’s dry electrode solutions demonstrate how this approach can optimize both performance and sustainability in next-generation energy storage systems.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt