A novel electrode material for high-performance energy storage devices is the silicon electrode made through dry electrode process. Advanced dry-processing techniques in the manufacturing of SiC anode provides high energy density during charging and discharging due to their exceptional specific capacity and conductivity. Stability after numerous cycles is guaranteed by their strong mechanical construction and lightweight design. These silicon electrodes, which are widely employed in high-energy-density batteries, electric vehicles, and renewable energy storage, contribute to the development of sustainable energy and offer potent answers to contemporary power requirements.

Silicon Electrode has a higher theoretical capacity, allowing for more energy storage and improving battery energy density.

The excellent conductivity of silicon materials enables fast charging and discharging performance, suitable for high-power applications.

The optimized dry-process improves the mechanical stability of SiC anode, reducing expansion and degradation.

There are stringent weight restrictions and a constant, reliable power source required for satellites and spacecraft. Due to their high energy density, dry-processed silicon electrode aid in lowering battery weight and supplying communication devices and satellite precision instruments with continuous power. This silicon carbide electrode lowers the possibility of mission disruptions brought on by insufficient energy and guarantees seamless data transfer and scientific exploration during space missions.

During operations, deep-sea detectors and underwater robots frequently struggle to recharge their batteries. Because of their high energy density, batteries that use dry-processed SiC anode can resist the intense pressure and frigid temperatures of the deep sea and facilitate long-duration deep-sea excursions, sample collecting, and image capture. This silicon carbide electrode increases human exploration of the deep sea and ensures stable equipment operation.

When traveling quickly, high-speed trains use a lot of energy and need to be recharged quickly. Train energy storage systems use dry-processed SiC anode, which can quickly absorb energy during brief station stops and maintain a steady power supply while in use. High silicon anode improves operating efficiency and punctuality by meeting the requirements for acceleration and maintaining high-speed operation.

Recent innovations in high silicon anodes and silicon carbide electrodes have transformed lithium-ion battery technology by addressing critical challenges like volume expansion and cycle life degradation. Through advanced nanostructuring and composite designs, these anode materials enhance battery performance, enabling longer electric vehicle (EV) ranges and faster charging capabilities. These breakthroughs not only improve energy storage efficiency but also support sustainable solutions for a greener future. As research into silicon electrodes progresses, these advanced materials are poised to dominate the battery market, reducing dependence on scarce resources and accelerating the global shift to renewable energy. By adopting these cutting-edge anode materials, industries can achieve unprecedented efficiency, making portable power more accessible and environmentally friendly for future generations.

Compared to traditional silicon electrodes, SiC anodes offer superior electrical conductivity and thermal management, making them ideal for high-demand applications like grid storage and aerospace. Research demonstrates that silicon carbide electrodes can achieve lifespans exceeding 1,000 cycles with minimal capacity fade while remaining compatible with existing manufacturing processes. The adoption of SiC anode technology marks a significant step toward reliable and scalable energy storage solutions. By prioritizing these advanced anode materials, industries can unlock cost reductions and performance improvements, fostering innovation in renewable energy integration and electric mobility. Ultimately, silicon carbide electrodes pave the way for a more sustainable and efficient energy landscape.

Pure silicon electrodes offer impressive theoretical capacities of over 3,500 mAh/g, but practical challenges like solid electrolyte interphase (SEI) formation have driven innovation toward high silicon anodes. Through alloying and advanced coatings, these hybrid anode materials deliver real-world energy density improvements of 20-30% over traditional graphite anodes. This advancement extends EV driving ranges beyond 500 miles and supports faster charging protocols critical for widespread adoption. As research focuses on hybrid solutions, including SiC anode integrations, the battery industry is on the verge of a transformative shift. By embracing high silicon anodes and other advanced anode materials, manufacturers can reduce costs, enhance sustainability, and drive the electrification revolution, ensuring a cleaner and more efficient future for mobility.

Get in Touch with Tsingyan for Energy Storage Solutions

at Anytime!

Unlock the future of advanced sensor technology with Tsingyan!

Our cutting-edge dry electrodes are designed for superior performance.

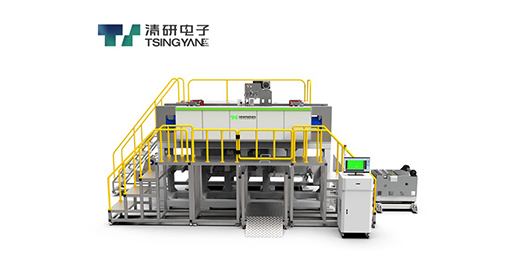

''Process Equipmentization'' Helps Promote the Large-Scale Mass Production of Dry Electrodes! CIBF2024

''Process Equipmentization'' Helps Promote the Large-Scale Mass Production of Dry Electrodes! CIBF2024

Exclusive Report by Gaogong | An Interview with Tsingyan Electronics: Ten Questions on the Necessity of Dry Electrodes

Exclusive Report by Gaogong | An Interview with Tsingyan Electronics: Ten Questions on the Necessity of Dry Electrodes

Win-Win Future | Tsingyan Electronics and Honggong Technology Reach a Strategic Partnership on Dry Film Innovation

Win-Win Future | Tsingyan Electronics and Honggong Technology Reach a Strategic Partnership on Dry Film Innovation