As the demand for high-energy-density batteries and sustainable manufacturing grows, dry electrode technology is emerging as a game-changing innovation in the battery industry. Unlike traditional wet electrode processes that rely on liquid binders and solvents, dry electrode technology introduces a slurry-free approach, streamlining manufacturing, reducing energy consumption, and significantly enhancing battery performance. This breakthrough is set to redefine the future of lithium-ion batteries, supercapacitors, and solid-state energy storage.

At its core, dry electrode technology replaces solvent-based slurry mixtures with a powder-to-film process. This method, often referred to as dry electrode processing, enables the direct application of composite dry electrode materials onto a conductive substrate. Compared to conventional dry battery electrode production, this approach not only improves efficiency and material compatibility but also minimizes environmental impact.

A key aspect of the process is roll-to-roll dry electrode manufacturing, which uses roll pressing techniques to create carbon-coated electrodes. This method is essential for producing long-cycle-life electrodes, making it ideal for applications that demand durability and high performance.

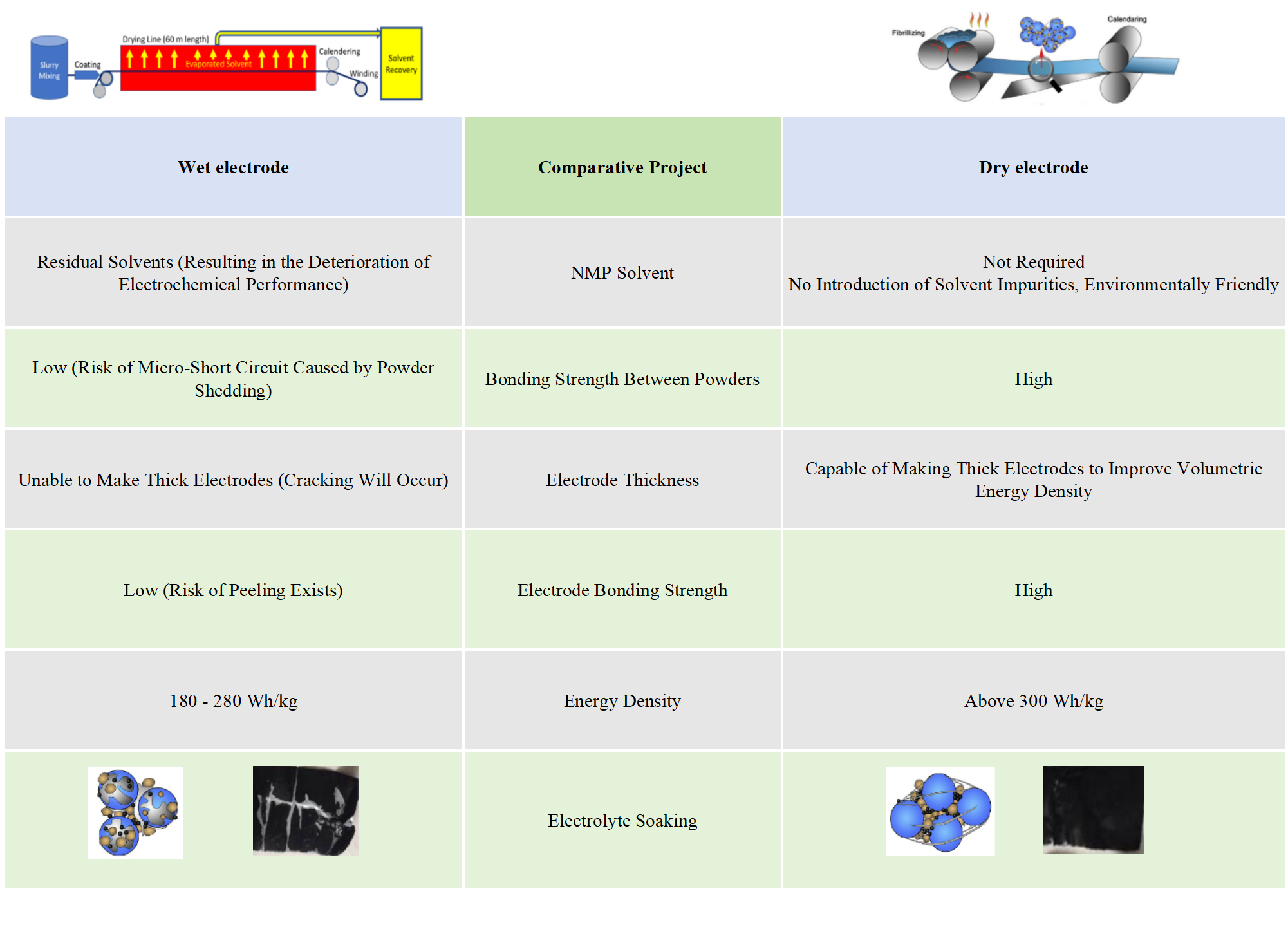

Traditional wet electrode manufacturing involves coating a substrate with a liquid slurry mixture of active materials, binders, and solvents, followed by a drying process. However, this method has notable drawbacks:

High energy consumption due to solvent evaporation and drying.

Use of hazardous chemicals, raising environmental concerns.

Longer production times, driving up manufacturing costs.

In contrast, dry-process electrodes eliminate solvents and drying steps entirely, offering compelling advantages:

Energy efficiency - Reduces energy consumption by up to 47%.

Faster production - The slurry-free process accelerates manufacturing, improving scalability.

Material versatility - Suitable for solid-state batteries, supercapacitors, and fast-charging applications.

Dry electrode production leverages advanced manufacturing methods, including:

Dry coating technology - A solvent-free approach for creating high-performance electrodes.

Roll-to-roll manufacturing - Ensures uniform coating and scalable production.

Roll pressing - Optimizes electrode density and conductivity for high-energy-density applications.

Innovations like Tsingyan’s dry electrodes showcase the potential of this technology for energy storage batteries, particularly in long-cycle-life and fast-charging scenarios.

Dry electrode technology is transforming more than just lithium-ion batteries. Its applications span across various energy storage solutions, including:

Electric vehicles (EVs) and portable electronics - Enhanced performance and energy efficiency.

Supercapacitors - Enabling rapid energy discharge and improved power density.

Solid-state batteries - Boosting safety and longevity for next-generation energy storage.

With continuous advancements, dry electrode technology is poised to drive the future of sustainable, high-performance energy storage.

The shift to dry electrode technology marks a significant leap forward in battery manufacturing. By adopting dry-process electrodes, manufacturers can achieve greater energy efficiency, reduced environmental impact, and superior battery performance. As innovators like Tsingyan refine dry electrode coating technology, the industry is moving closer to a future where solid-state batteries, supercapacitors, and high-energy-density solutions are more accessible than ever.

With its benefits of faster production, enhanced durability, and eco-friendly processes, dry electrode technology is shaping the next generation of energy storage solutions.

If you are interested, there are other related dry electrode blogs:

What Is Dry Electrode Coating Technology

Dry Electrode Processing & Manufacturing

Dry Battery Electrode Technology

Dry Battery Electrode Manufacturing Process and Machine

Dry Electrode Coating Technology - DBE Battery

Dry Coating Technology & Process

Battery Electrode Foil Drying Process

Tesla Dry Electrode Technology

Dry Processed Vs. Solution Processed Electrodes