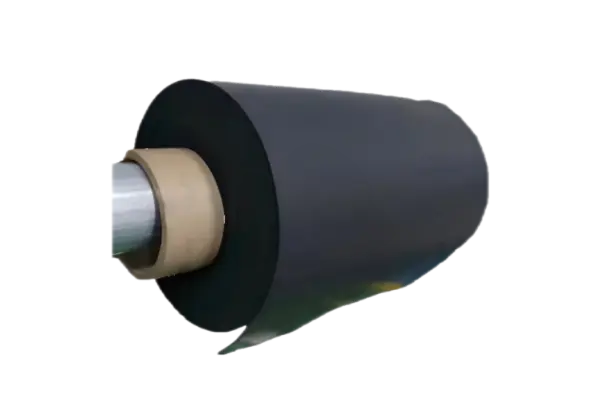

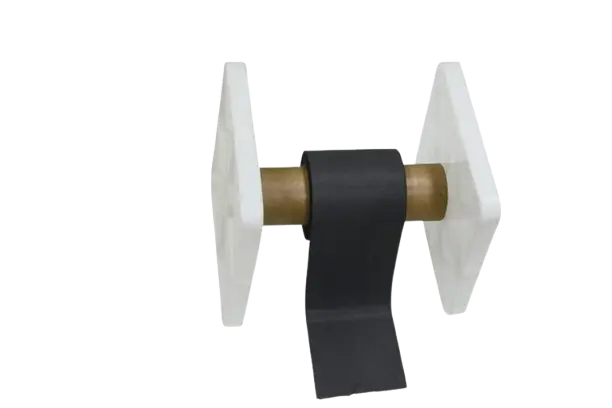

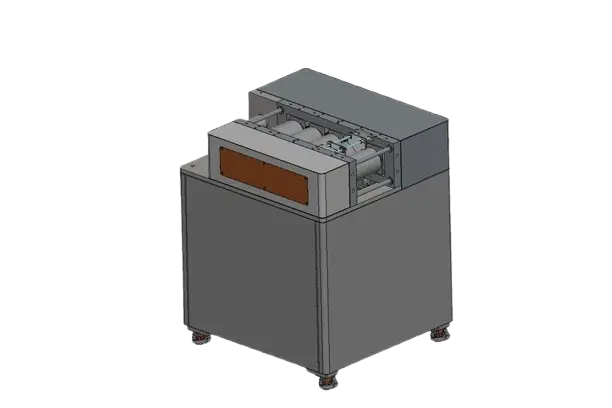

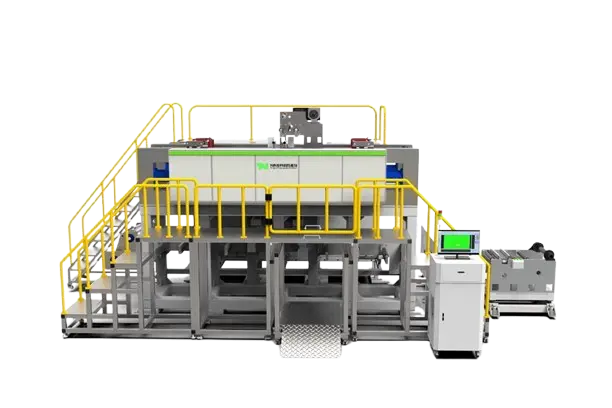

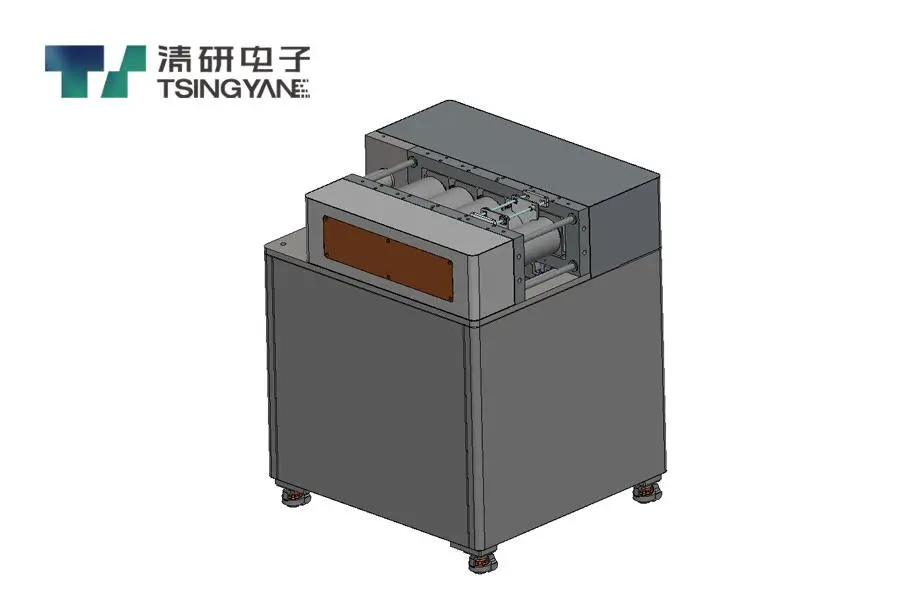

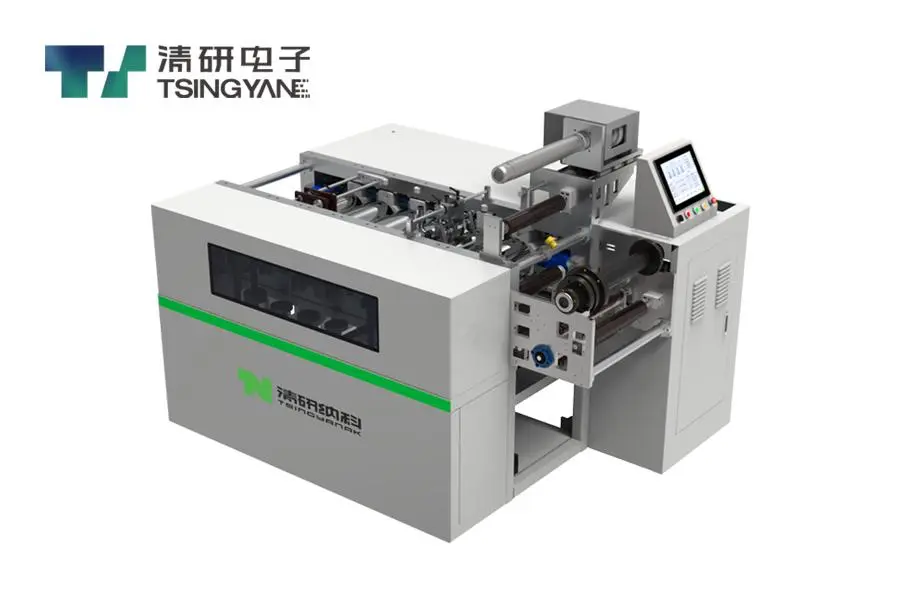

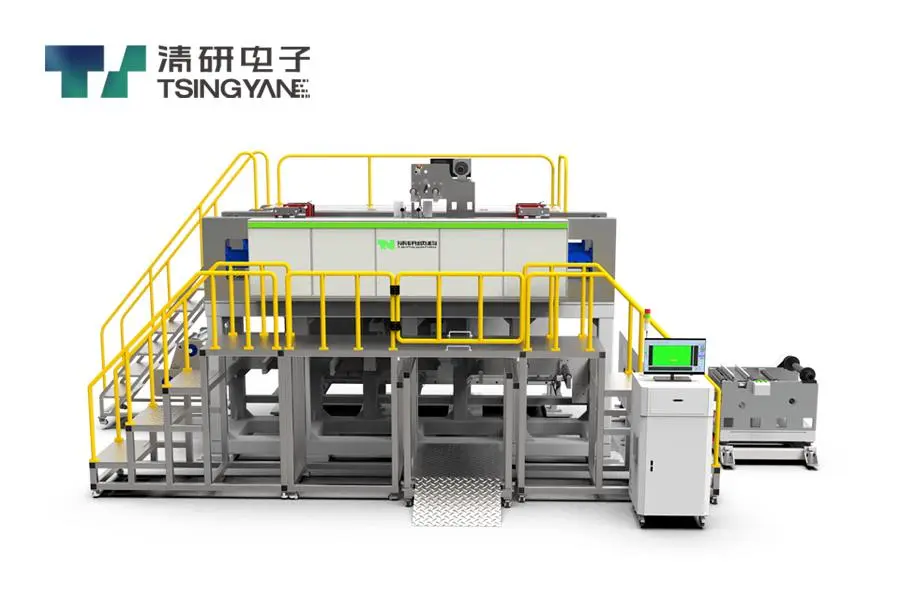

Equipment for dry electrodes is a crucial tool for the manufacturing of dry electrodes. It is mainly used to mix, compact and shape the dry electrode materials. The equipment applies pressure to the materials through a series of high-precision rollers to ensure the uniform compaction of the materials and can effectively control the thickness and density of the electrodes. Generally, these equipment have a high degree of automation, operate stably, and are capable of precisely mixing the binders, active materials and so on to produce high-quality electrodes, which is of great significance for improving product performance and production efficiency.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt